Projects

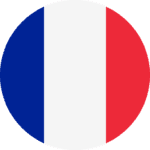

Kecor

Winner of the ADEME i-Nov Competition: new solvent-free, VOC-free paint technology to replace industrial anti-corrosion paints.

Conventional industrial anti-corrosion paint systems contain solvents (20 to 70% VOCs).

Applied as a thin film, they require several coats spaced 24 to 48 hours apart to ensure corrosion protection.

The present KECOR project aims to develop a new single-component, strictly solvent-free (VOC-free) paint technology that avoids any CO2 emissions or discharge into the environment and will offer unmatched technical performance objectives. This technique will be of great economic interest compared to existing solutions (productivity gains, etc.).

– Innovation: single-component solvent-free resin

– Environment: no VOC or CO2 emissions during paint application

– Performance: ensuring long-lasting durability of protected equipment

– Safety: preserving the health of painters/applicators implementing the new KECOR technique

– Significant productivity gains (x3)

The KECOR project thus represents a significant advance towards greener and more efficient industrial practices, establishing new standards of performance, safety, and economy in the industrial paint sector.

Matex

MATEX and the LOTUS effect

Multimaterial at Extreme Exposure Conditions (acronym)

Project in partnership with ICMN (Interfaces, Confinement, Materials and Nanostructures) and GREMI (Research Group on the Energetics of Ionized Media), laboratories affiliated with CNRS (University of Orléans)

The economic context reveals a strong demand for surface coatings with specific properties such as self-cleaning, anti-fouling, anti-icing, and anti-soiling. So-called superhydrophobic coatings, based on solvent-free polyurethane resins, meet these sought-after properties. They are achieved either through specific surface chemistry (fluorine, silicone) or by specific surface texturing to obtain a multi-scale topography (lotus effect).

Chemical modification is an interesting approach for resins applied directly on large surfaces in construction or civil engineering. Furthermore, surface texturing techniques are considered to produce prefabricated membranes textured by laser/plasma, which can then be adhered on site. These coatings can cover specific elements such as valves for liquefied gas or oil transport to ensure protection in winter, or external portions of an aircraft or NABLA coupling systems used for train rail fixation.

This project requires the use of additives with the resin to « boost » surface properties (fluorinated silicas, graphene) without using solvents. Expertise in polymer chemistry and physico-chemistry will be needed. Plasma texturing techniques also require highly specialized skills and equipment. Additionally, the processes must be designed to be viable at an industrial scale.

Matex

MATEX and the LOTUS effect

Multimaterials in Extreme Conditions (acronym)

Project in partnership with ICMN (Interfaces, Confinement, Materials and Nanostructures) and GREMI (Research Group on Energetics of Ionized Media), laboratories affiliated with CNRS (University of Orléans)

The economic context highlights a strong demand for surface coatings with specific properties such as self-cleaning, anti-fouling, anti-icing, or anti-fouling. These so-called superhydrophobic coatings, based on solvent-free polyurethane resins, meet these desired properties. They are obtained either through a special surface chemistry (fluorine, silicone), or through specific surface texturing to create a multi-scale topography (lotus effect).

Chemical modification is an interesting approach for resins directly applied on large surfaces in construction or civil engineering. Moreover, surface texturing techniques are considered to produce prefabricated membranes textured by laser/plasma, which are then glued on-site. These coatings can cover specific elements such as valves for transporting liquefied gases or petroleum to provide winter protection, or external surface portions of aircraft or NABLA fittings systems used for securing train rails.

This project requires the use of additives with the resin to “boost” surface properties (fluorinated silicas, graphene) without using solvents. Expertise in polymer chemistry and physico-chemistry will be necessary. Surface texturing by plasma also requires specialized skills and advanced equipment. Furthermore, the processes must be designed to be viable at an industrial scale.

NEWSKIN

CITEPH

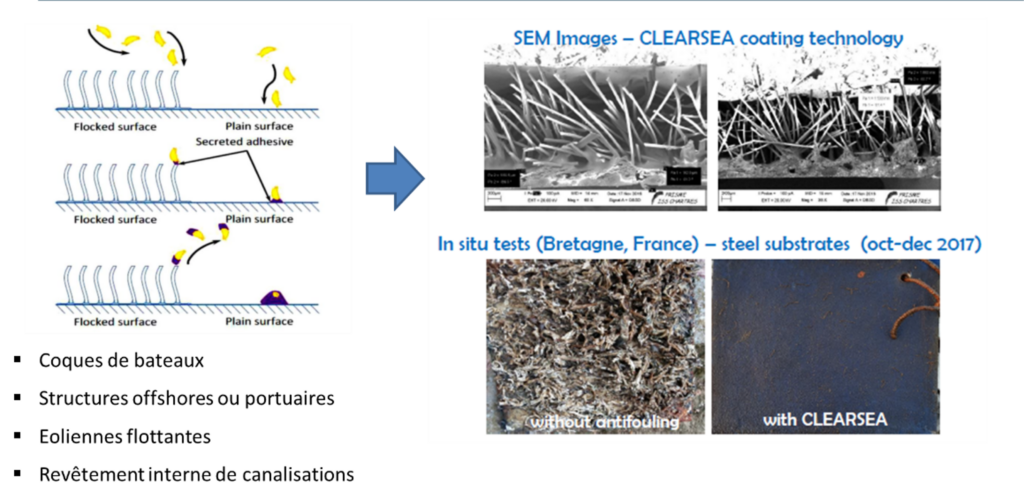

Clearsea

- The application of a thick anti-corrosion protective resin layer (approximately 0.7 mm, the required thickness will be validated by this project) directly on the ship’s hull: this coating is a homogeneous system, without microporosity and poses no environmental risk (two-component resin, 100% solids content).

- The CLEARSEA finishing layer, modified to be applied electrostatically, will be immediately sprayed onto the first layer of the same anti-corrosion resin, onto which the fibers will be fixed by electrostatic projection. Thus, the anti-corrosion protective coating and the CLEARSEA finishing layer will be perfectly homogeneous (system weight: approximately 1.3 kg/m²), with no risk of detachment, and will perfectly follow the substrate geometry. The system is intended to be inspected and possibly renewed in dry dock every 10 years.

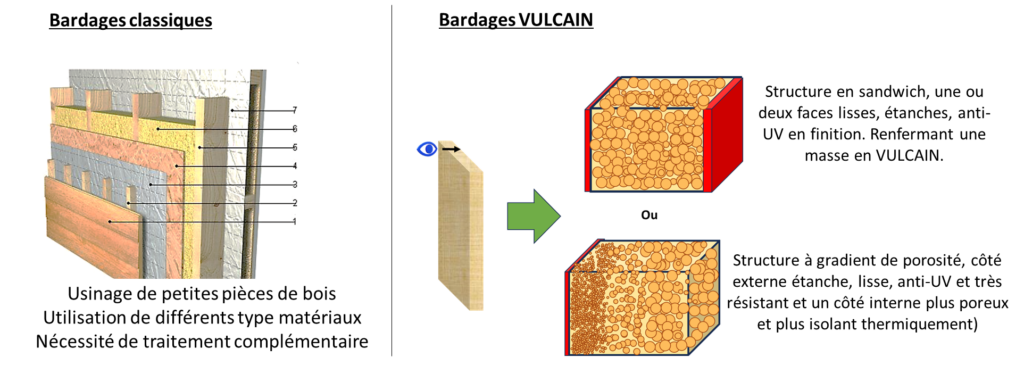

Vulcain